Asset Performance Management: A Critical Strategy for Businesses

- Extending the Life of Equipment: Regular maintenance extends the life of equipment, resulting in long-term cost savings.

- Failure Prevention: Effective maintenance programmes guarantee continuity of production by preventing unexpected failures.

- Cost Optimisation: Planned maintenance activities are more cost-effective than emergency repairs.

- Increased Efficiency: Regular maintenance allows equipment to operate more efficiently and save energy.

- Data-Driven Decision Making: Technologies such as CMMS and IoT make maintenance decisions data-driven.

Fundamentals of Asset Performance Management

Asset performance management is a critical function for businesses to ensure that their physical assets operate at maximum efficiency. This form of management is designed to extend the life of equipment, improve operational efficiency and reduce costs. In modern businesses, asset performance management is a key way to gain competitive advantage and support sustainable growth.

Enhancing Asset Performance with Technology

Asset performance management is vital for businesses to remain competitive and succeed in the marketplace. This form of management is essential to reduce costs, improve operational efficiency and support sustainable growth. Optimising your business’ asset performance will underpin your future success.

In today’s business world, technology plays a critical role in managing and optimising asset performance. The tools and systems enabled by technology are enabling businesses to manage their assets more effectively, reduce costs and improve operational efficiency. Here are some highlights of how technology is improving asset performance:

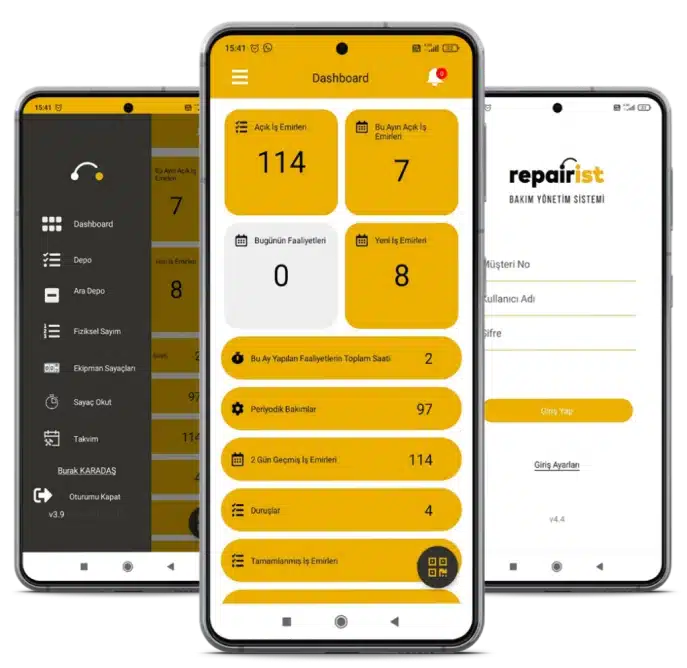

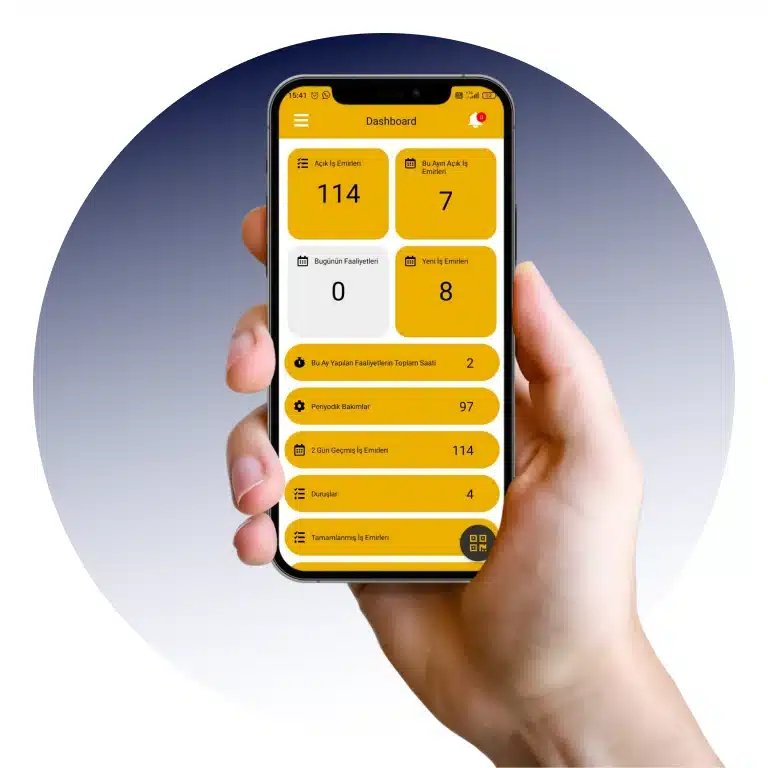

Work Order Tracking

Preventive Maintenance

Scheduled ,Incidental Maintenance

Warehouse and Racking Systems

Cost Analysis

Stock, Spare Parts Tracking

Internet of Things (IoT) and Sensor Technology:

IoT devices and sensors collect real-time data of equipment and machines. This data is used to monitor equipment status, evaluate performance and detect potential problems early. For example, temperature or vibration sensors can prevent failures by detecting overheating or abnormal operating conditions of equipment at an early stage.

Advanced Data Analytics

The big data collected is processed with advanced analytical tools and software. These analyses help determine the performance, lifetime and maintenance needs of the equipment. Using machine learning and artificial intelligence algorithms, meaningful insights and recommendations are derived from the data. This improves maintenance planning and decision-making processes.

Integrated maintenance management systems such as CMMS (Computer Aided Maintenance Management System) automate and streamline maintenance processes. These systems combine functions such as maintenance planning, inventory management and work order management, making maintenance activities more efficient and effective.

The role of technology in improving asset performance not only means cost savings and increased efficiency for businesses, but also creates more reliable, sustainable and competitive operations. By utilising these technological tools strategically, businesses can build a solid foundation for future success.