Efficiency and Sustainability in the Digital Age

Competition in the manufacturing world is becoming increasingly challenging. Rising customer expectations, cost pressures, and sustainability goals are pushing businesses to seek more strategic solutions in maintenance management. Traditional maintenance methods alone are no longer sufficient. At this point, Lean Maintenance Management comes into play.

At its core, lean maintenance aims to eliminate waste, increase equipment efficiency, and embrace a culture of continuous improvement. This approach foresees that responsibility is shared not only by maintenance teams but also by the entire organization. One of the strongest aspects of lean maintenance is that employees take an active role in all areas, from daily maintenance activities to engineering improvements.

Core Principles of Lean Maintenance

Lean maintenance originates from lean manufacturing philosophy and is adapted to maintenance management. The key principles in this system are:

1. Zero breakdown target

→ Minimizing unplanned downtime

2. Equipment reliability

→ Ensuring machines and devices always operate at peak performance

3. Employee involvement

→ Including operators in maintenance processes (autonomous maintenance)

4. Continuous improvement (Kaizen)

→ Progressing through small but steady improvements

Classifications in Lean Maintenance Management

Lean maintenance groups maintenance activities within businesses under three main categories.

1. Breakdown Maintenance

- Emergency breakdowns: Unexpected equipment stoppages that require quick intervention.

- Planned breakdowns: Repairs that are anticipated and scheduled in advance.

The goal of breakdown maintenance is to minimize repair times and reduce production losses to a minimum.

2. Preventive Maintenance

- Daily maintenance: Cleaning, lubrication, inspections, and tightening operations carried out by operators.

- Periodic maintenance: Scheduled maintenance activities performed at specific intervals.

- Predictive maintenance: Using sensors, IoT technologies, and data analysis to predict failures before they occur.

Preventive maintenance extends equipment life, reduces costs, and increases operational reliability.

3. Corrective Maintenance

- Occupational health and safety (OHS): Improvements made to ensure work and equipment safety.

- Easy maintenance: Making equipment more accessible and easier to maintain through simple interventions by employees.

- Design modifications: Engineering improvements that aim for zero breakdowns through better design.

This approach supports the Kaizen culture and spreads continuous improvement across the entire organization.

Integration of Lean Maintenance and CMMS

The success of lean maintenance largely depends on proper data management and digitalization. This is where CMMS (Computerized Maintenance Management System) software comes into play.

With CMMS, businesses can:

- Plan and track all maintenance activities digitally

- Manage breakdown records, maintenance history, and performance reports in one central system

- Use IoT and artificial intelligence integrations for predictive maintenance to foresee failures in advance

- Record operators’ daily maintenance tasks digitally, strengthening the culture of autonomous maintenance

- Document Kaizen practices digitally, making continuous improvement measurable

In short, when CMMS and lean maintenance come together, businesses achieve higher efficiency at lower costs.

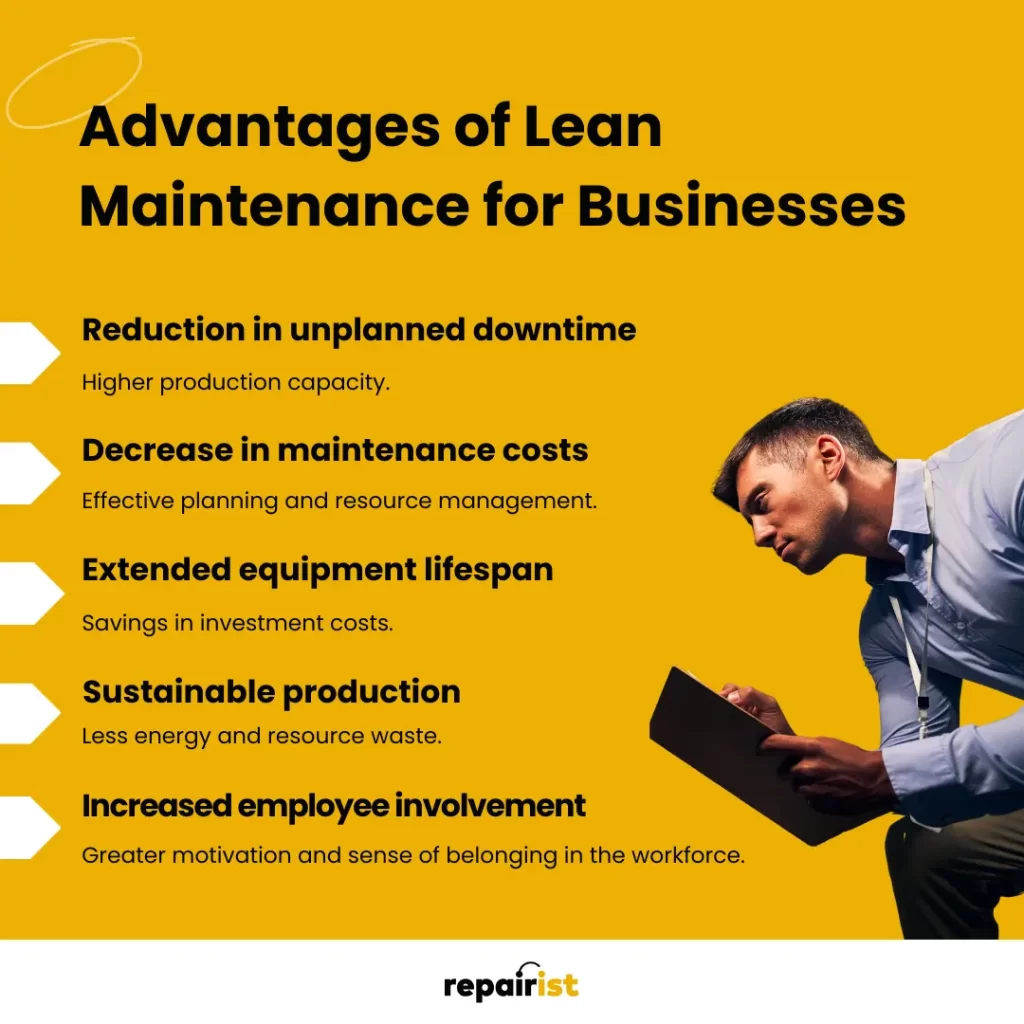

Advantages for Businesses

Lean Maintenance Empowered by Digital Transformation

With Industry 4.0, maintenance management is also undergoing a transformation.

- Predictive maintenance with IoT sensors

- AI-powered maintenance planning

- Field management through mobile applications

- Real-time reporting and KPI tracking

In this way, businesses can plan not only for today but also for the future.

Lean Maintenance Management streamlines maintenance processes, increases equipment efficiency, and reduces costs. CMMS software brings this approach into the digital environment, making it sustainable, measurable, and scalable.

Next Steps

Have you received sufficient information about “Lean Maintenance Management” ?

repairist is here to help you. We answer your questions about the Maintenance Management System and provide information about the main features and benefits of the software. We help you access the repairist demo and even get a free trial.

Aybit Technology Inc.